In the beautiful Tuscan village of Santa Croce sull’Arno, Luigi Caroti and Rose Marie Moya spend their days creating exceptional leather at the Conceria 800 tannery. Luigi and Rose Marie combine a shared lifetime of vegetable tanning experience with an innovative eye toward new product development.

“We strive to differentiate ourselves from other tanneries, we always want to offer something new and better”

– Rose Marie

The son of a shoemaker, Luigi has worked with leather since childhood when, at the age of 14, he started working in a local tannery to earn pocket money. Luigi finds inspiration everywhere, and never allows his creativity to be stifled by the supposed challenges of a given idea. “Getting the tanning mixture right is the most challenging aspect of creating new leather,” he says. “The slightest difference here or there will produce a completely different effect on the leather.”

“It’s nice to keep this traditional method alive – when you touch the leather, you can really feel the difference it makes”

– Rose Marie

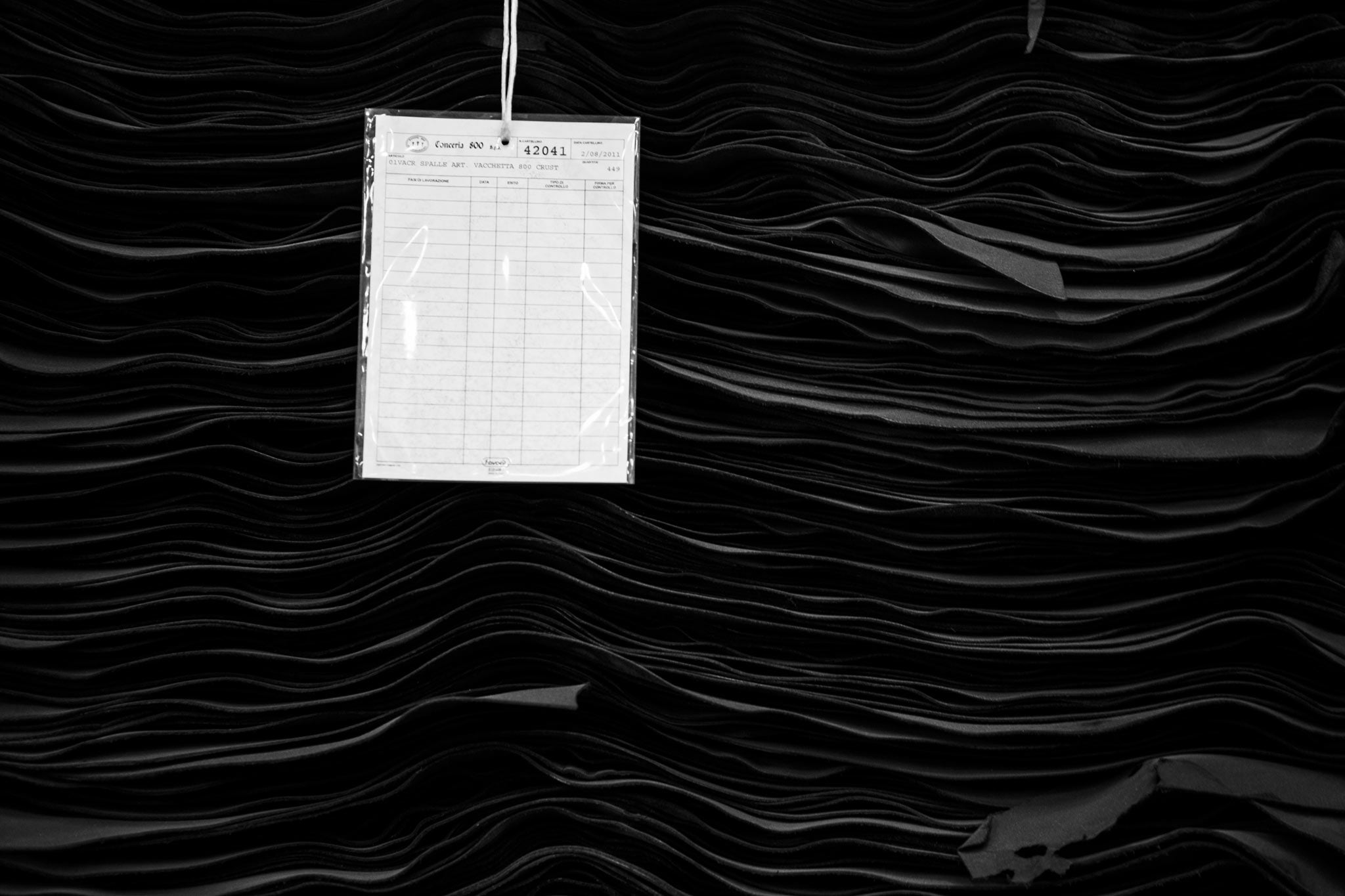

The tannery sources raw materials from all over the world. Hides come from Brittany, the French region famous for producing the finest hides for leather. The hides are tanned the traditional way, in large drums containing a blend of water and bark powders, such as quebracho from Argentina, mimosa from Australia and Brazil, and chestnut powder from southern Europe.

As well as drum tanning, Conceria 800 maintains the ancient tradition of pit tanning. Pit tanning sees hides progress through three pits containing vegetable-tanning mixtures of different strengths, with the concentration of each mixture changing from one pit to the next. Smaller quantities of leather are produced via this time-consuming method as the hides stay in each pit for about ten days. But at Conceria 800, they believe it’s worth the effort. “It’s nice to keep this traditional method alive – when you touch the leather, you can really feel the difference it makes,” says Rose Marie.

Many of the team members at Conceria 800 were born and raised near the tannery, with a deep understanding and appreciation for the art of vegetable-tanned leather. The familial atmosphere encourages the team to experiment whenever the mood strikes them.

In fact, the leather used in Troubadour’s iPad cases is the result of one such scenario. Luigi noticed the wonderful look and feel of a piece of leather that had been used to change plates in machines. The team decided to work to reproduce that effect, experimenting with many different mixtures before they arrived at the version that pleased them. And, hopefully, you!